- MenuBack

-

Home

Home - Solutions

- Anticorrosion, metal structures and objectsAnticorrosion, metal structures and objects

- Concrete, walls and exterior facadesConcrete, walls and exterior facades

- Roofs & WaterproofingRoofs & Waterproofing

- Balconies and terracesBalconies and terraces

- Floors: garages, warehouses, technical rooms, parkingsFloors: garages, warehouses, technical rooms, parkings

- Products

- References

- RD Coatings Academy

- Our company

- Our company

- News

- Contact

Delivery 48h

Secure payments

Technical & commercial support

Calculate here the amount of paint needed for your project

RD-Monoguard SG

Go totechnical sheet

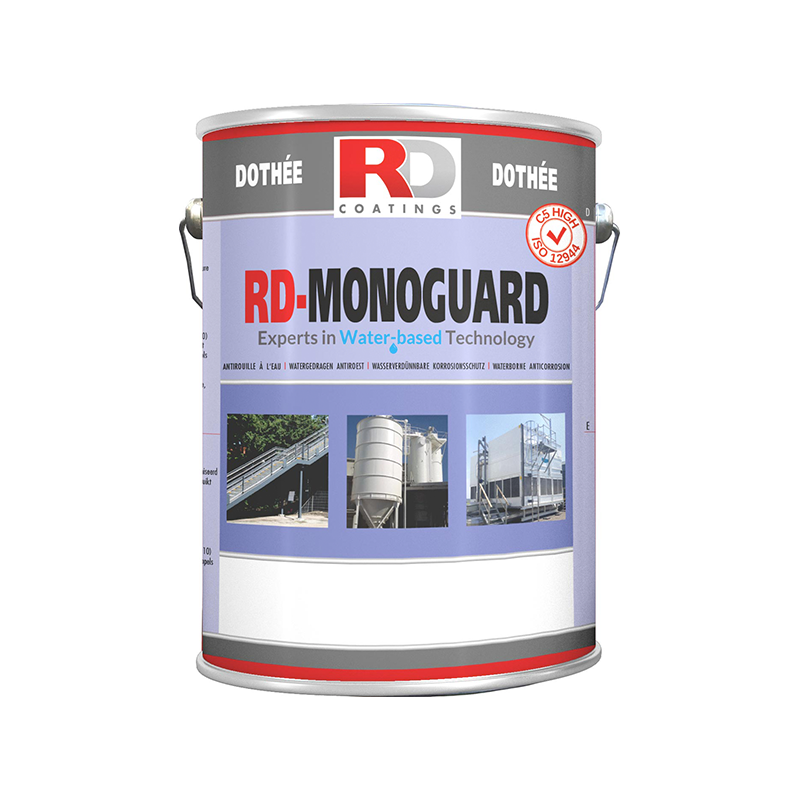

The Benchmark in High-Performance Anti-Rust Paint for C4 and C5 Environments.

Discover RD-Monoguard, a single-component water-based anticorrosion paint, the first in the world to be certified C5 VH (Very High) by an accredited and independent laboratory!

Thanks to its innovative formulation, RD-Monoguard belongs to a new generation of water-based anticorrosion coatings, providing long-lasting protection equivalent to traditional epoxy-polyurethane systems, with numerous advantages:

✔ Universal adhesion

✔ Optional SA 2.5 blasting

✔ Ready-to-use paint

✔ Ultra-fast drying

Outstanding Performance!

RD-Monoguard combines the essential properties required for metal protection coatings:

🔸 Excellent adhesion and corrosion protection

🔸 High resistance to water, erosion, and UV rays

🔸 Exceptional durability

Tested by independent laboratories, it is certified for protecting metal structures and objects in marine and industrial environments classified C4 and C5. Its high-performance formulation ensures protection for over 25 years, in accordance with ISO 12944.

An Eco-Friendly and Safe Alternative

Choosing RD-Monoguard means opting for a safer, easier, and more environmentally friendly solution than traditional solvent-based systems.

✅ Single-component and water-based

✅ Reduced VOC emissions

✅ Significant waste reduction

✅ More comfortable and safer application

RD-Monoguard: Innovation in Metal Protection.

Technical sheet RD-Monoguard SG

Download technical sheetDescription of the product

USE:

Fast drying Primer/Finish high performance anti-corrosion coating with universal adherence.

FEATURES:

Single component water-based coating based on a special blend of innovative resins for the protection of metal surfaces, objects and engineered structures against corrosion and weathering. RD-Monoguard is a DTM (Direct-To-Metal) type of coating that can be applied directly to various type of ferrous and non-ferrous metals. Its special formulation and ingredients offer incredible durability when it comes to protecting steel against corrosion, even without priorly blasting the surface.

RD-Monoguard is water-based, easy to handle, safe and has no fire risks. It is a fast-drying coating system that greatly reduces downtime during installation and increases on-site labour productivity.

Virtually odour free, it does not affect neighbouring occupants and can therefore be used in occupied buildings.

RD-Monoguard is UV resistant and its film forms a neat and tidy enamel type of finish.

Tested to be used in the most severe environments, RD-Monoguard protects valuable assets worldwide 24/7 including bridges, tanks, etc.

RD-Monoguard is part of the SCS – Single Coating System - product group.

SUBSTRATES:

Steel, new and old galvanised steel, stainless steel, aluminium, copper, …

Systems

Steel located in very aggressive marine & industrial environments – C5 Very High / VH | Wet film thickness in microns / mils | Dry film thickness in microns / mils | Consumption per m² / pi² par gallon | Comments | |

1st layer | RD-Monoguard | 210 / 8.2 | 90 / 3.6 | 0,21 l / 195 | Very high lifespan > 25 years |

2nd layer | RD-Monoguard | 210 / 8.2 | 90 / 3.6 | 0,21 l / 195 | |

3rd layer | RD-Monoguard | 210 / 8.2 | 90 / 3.6 | 0,21 l / 195 | |

TOTAL | 270 / 10.8 | 0,63 l / 65 | |||

Steel located in aggressive marine & industrial environments – C5 High | Wet film thickness in microns / mils | Dry film thickness in microns / mils | Consumption per m² / ft² per gallon | Comments | |

Primer | RD-Monoguard | 233 / 9,3 | 100 / 4 | 0,23 l / 175 | High lifespan > 15 years |

Finish | RD-Monoguard | 233 / 9,3 | 100 / 4 | 0,23 l / 175 | |

TOTAL | 200 / 8 | 0,46 l / 87 | |||

Other option: | |||||

Primer | RD-Monoguard | 230 / 9 | 100 / 4 | 0,23 l / 175 | High lifespan > 15 years |

Finish | RD-Hydrograff HP Gloss | 105 / 4,2 | 50 / 2 | 0,10 l / 390 | |

TOTAL | 150 / 6 | ||||

Other option in case of old and rusty surface: | |||||

Primer | RD-Elastometal | 386 / 15,4 | 220 / 8,8 | 0,48 kg / 106 | High lifespan > 15 years |

Finish | RD-Monoguard | 186 / 7,4 | 80 / 3,2 | 0,19 l / 219 | |

TOTAL | 300 / 12 | ||||

Steel located in aggressive marine & industrial environments – C4 | Wet film thickness in microns / mils | Dry film thickness in microns / mils | Consumption per m² / ft² per gallon | Comments | |

Primer | RD-Monoguard | 174 / 7 | 75 / 3 | 0,17 l / 234 | High lifespan > 15 years |

Finish | RD-Monoguard | 174 / 7 | 75 / 3 | 0,17 l / 234 | |

TOTAL | 150 / 6 | 0,34 l / 117 | |||

Other option: | |||||

Primer | RD-Monoguard | 186 / 7,4 | 80 / 3,2 | 0,19 l / 219 | High lifespan > 15 years |

Finish | RD-Hydrograff HP Gloss | 83 / 3,3 | 40 / 1,6 | 0,08 l / 488 | |

TOTAL | 120 / 4,8 | ||||

Other option in case of old and rusty surface: |

|

|

|

| |

Primer | RD-Elastometal | 315 / 13 | 175 / 7 | 0,4 kg / 130 | High lifespan > 15 years |

Finish | RD-Monoguard | 186 / 7,4 | 80 / 3,2 | 0,19 l / 219 | |

TOTAL |

| 255 / 10,2 | |||

Steel located in moderate environments – C3 | Wet film thickness in microns / mils | Dry film thickness in microns / mils | Consumption per m² / ft² per gallon | Comments | |

Primer | RD-Monoguard | 128 / 5,1 | 55 / 2,2 | 0,13 l / 319 | High lifespan > 15 years |

Finish | RD-Monoguard | 128 / 5,1 | 55 / 2,2 | 0,13 l / 319 | |

TOTAL | 110 / 4,4 | 0,26 l / 160 | |||

Other option in case of old and rusty surface: |

|

|

|

| |

Primer | RD-Elastometal | 214 / 8,5 | 120 / 4,8 | 0,27 kg / 190 | High lifespan > 15 years |

Finish | RD-Monoguard | 186 / 7,4 | 80 / 3,2 | 0,19 l / 219 | |

TOTAL |

| 200 / 8 |

| ||

Risks of chemical spills or graffitis:

The system can be top coated by one or two coats of RD-Hydrograff HP Clear High Gloss if not already used in the system.

Indicated consumption is theoretical and does not consider potential losses during application. It can also be influenced by the porosity of the substrate.

Application instructions

APPLICATION CONDITIONS:

Ambient temperature: minimum 5°C (41°F) – optimal between 12 and 25°C (54 and 77°F).

Relative humidity: maximum 80%

Surface temperature must be minimum 3°C (5°F) above dew point.

APPLICATION MEANS:

Brush, roller or airless (nozzle size: 010–012)

Application by airless is recommended and makes it easier to reach the recommended thicknesses. Use a device that allows a minimum pressure of 70-150 bar / 1000 - 2000 psi at the outlet.

PREPARATION OF THE SUBSTRATE:

The substrate must be clean: dry, degreased and dust free. Non adhering elements such as older coatings or rust must be removed. Different type of surface preparation are possible:

1/ Remove rust manually or by power tool to ST2 – ISO 8501-1/SSPC SP2 or SP3.

2/ Blasting to SA 2½ - ISO 8501-1/NACE3/SSPC SP6.

3/ High pressure washing following SSPC SP12 WJ4.

Aluminum: clean with sulfuric acid diluted to 10%.

On new galvanized steel: preferably clean with RD-Eco PowerClean detergent diluted with water or use a conventional detergent.

Stainless steel: preferably clean with RD-Eco PowerClean detergent diluted with water or use a conventional detergent.

Copper: clean with hydrochloric acid diluted to 10% and rinse with water.

Repainting alkyd resin-based paints: Perform an adhesion test beforehand if the paint is recent or less than a year old. Optionally, lightly sand the surface before painting.

DILUTION:

Product is ready-for-use. Dilute with maximum 3% water when applying by airless or in warm weather conditions (> 25°C / > 77°F).

DRYING TIME (20°C - 68°F):

Touch dry: +/- 1 hour depending on thickness

Recoatable: +/- 2 hours depending on film thickness

Possible to apply wet on wet in special conditions.

CLEANING OF TOOLS:

Water

SPECIFICITIES:

Mix well before use.

Technical data

FINISH (Gardner 60°):

Semi-Gloss - Minimum 70% +/- 5 (Gardner 60°), depending on the shade.

COLOURS:

White. Also available in clear, check RD-Monoguard Clear.

RAL, NCS and bespoke colours. Available on RD Coatings dispensing system.

DENSITY:

1.15 +/- 0.05 g/cm³

SOLIDS CONTENT:

In weight: 51 % +/-2

In volume: 43 % +/-2

VISCOSITY:

30 - 50 P (Brookfield 20RPM)

VOC CONTENT:

< 45 g/l

FLASH POINT:

Not flammable

STORAGE:

Minimum 24 months protected from frost and excessive temperatures in its original closed packaging.

Norms and tests

SALT SPRAY | ISO 9227 / ISO 4628 |

WATER CONDENSATION | ISO 6270 / ISO 4628 |

ADHESION | ISO 2409 |

HARDNESS PERSOZ | ISO 1522 |

HARDNESS PENCIL | ISO 15184 |

| ISO 16000-6 / VOC Classification in France |

Safety data

Information related to hygiene and to safety can be found in the Safety Data Sheet available on request.

These specifications are given for information. Since the manufacturer is not able to check the application of the products, he cannot accept any responsibility for it. This technical data sheet replaces all previous editions.

VERS. S051/240220

The Benchmark in High-Performance Anti-Rust Paint for C4 and C5 Environments.